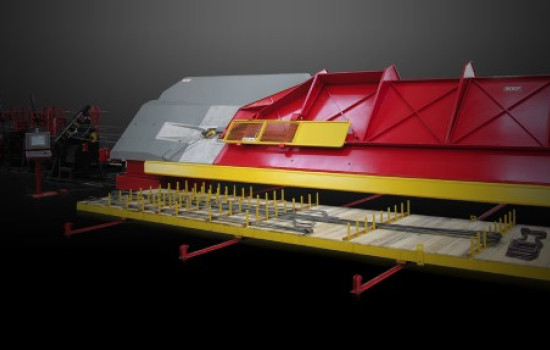

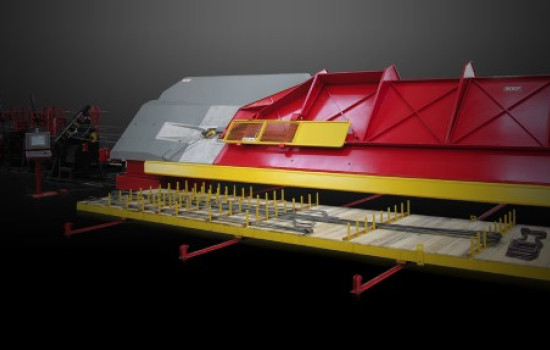

Planet

SHAPE FORMING AND STIRRUP BENDING FROM COIL

The PLANET Plus machines represents the highest technological development in the field of multi-unctional off-coil machinery (shape forming, stirrup bending, wire straightening and radius forming).

Advanced functionalities for a wide range of needs:

Shape forming: Create shapes with one or more bends on both sides.

Stirrup bending: Produce medium and large-sized flanges with the utmost precision.

Straightening: Straighten coiled round bars quickly and reliably.

Calendering: Produce calendered elements, even with variable bending radii, for maximum flexibility.

Circle creation: Produce circles automatically for an optimized workflow.

Unparalleled advantages:

Exceptional versatility: A wide range of accessories to meet the most diverse production needs.

Complete automation: Eliminates manual operations, ensuring an optimized and continuous work cycle.

AFS (Advanced Feeding System) and electronic pointer: Automatically manage the individual straightening of round bars for greater precision.

Guaranteed safety: Eliminates manual intervention during the bending phase, protecting the operator.

Single bending unit: Simplified and faster work cycle for increased efficiency.

Exclusive pins and devices: Expands the range of possible processes, even for complex shapes.

Innovative workstation design: Facilitates the production of large-sized brackets and profiles, the collection of the finished product, and its conveying to collection systems.

Unlimited dimensional flexibility: Works on a wide range of dimensions and shapes, even complex ones, to meet any requirement.

Variable radius bending software: "Virtual pin" function for large radius bends for maximum design freedom.

The PLANET Plus guarantees maximum flexibility, productivity, and quality of the finished product.

Planet 22 Plus Multiradius

SHAPE FORMING AND STIRRUP BENDING FROM COIL

COIL ∅10 - ∅22 mm (#3 - #7)

Double wire up to ∅16 mm (#5)

AFS 3 (Advanced Feeding System) Generation III

The pressure exerted on each individual wire

Complete power unit with winch, portable straightening unit and motorized pre-driving roller for pre-straightening

Motorised collection trolley, belt conveyor and chain collector conveyor are available

Bending pins accordingly to international rules

The payoffs provide automatic motorization and are available in 2 versions: for rolls up to 5 t or up to 8,3 t

Ring forming tool (optional) up to Ø20 mm (#6)

PLANET 22 Plus Press 3D

SHAPE FORMING AND STIRRUP BENDING FROM COIL

COIL ∅10 - ∅22 mm (#3 - #7)

• Double wire up to ∅16 mm (#5)

• AFS 3 (Advanced Feeding System) Generation III

• The pressure exerted on each individual wire

• Complete power unit with winch, portable straightening unit and motorized pre-driving roller for pre-straightening

• Motorised collection trolley, belt conveyor and chain collector conveyor are available

• Bending pins accordingly to international rules

• The payoffs provide automatic motorization and are available in 2 versions: for rolls up to 5 t or up to 8,3 t

• 3D press

Request information

PLANET 22 Plus W Press 3D

SHAPE FORMER AND STIRRUP BENDER FROM COIL

COIL ∅10 - ∅22 mm (#3 - #7)

• Double wire up to ∅16 mm (#5)

• Rollers are equipped with 3 grooves: two are dedicated to the simultaneous processing of 2 wires (up to 16 mm (#5)) and one for single wire (up to 22 mm (#7))

• AFS 3 (Advanced Feeding System) Generation III

• The pressure exerted on each individual wire

• Multi-wire pre-feeder

• Motorised collection trolley, belt conveyor and chain collector conveyor are available

• Bending pins accordingly to international rules

• The payoffs provide automatic motorization and are available in 2 versions: for rolls up to 5 t or up to 8,3 t

• Press 3D

Request information

Planet 16 Advanced

NEW - PLANET 16 ADVANCED

Shape forming and stirrup bender

Coils Ø8 - Ø16 mm (#3 - #5)

• New compact shear

• (Advanced Feeding System) Generation IV

• Independent pressure control for each wire

• Electric collecting carriage

• Evertything electric except the shear

• Kit power consumption

• TwinSense ready

Request information

PLANET 16 Advanced Press 3D

SHAPE FORMING AND STIRRUP BENDING FROM COIL

COIL ∅8 - ∅16 mm (#3 - #5)

• Double wire up to ∅12 mm (#4)

• Option double wire up to Ø14 mm

• Optional Press 3D up to Ø16 mm (#5)

• Multiwire pre-feeding unit

• New compact shear

• AFS 4 (Advanced Feeding System) Generation IV

• Independent pressure control for each wire

• A wide variety collecting device for stirrup and shapes are available

• Bending pins accordingly to national rules

• Energy saving and efficiency

Request information

Planet 22 Plus W

SHAPE FORMING AND STIRRUP BENDING FROM COIL

COIL ∅10 - ∅22 mm (#3 - #7)

• Double wire up to ∅16 mm (#5)

• Rollers are equipped with 3 grooves: two are dedicated to the simultaneous processing of 2 wires (up to 16 mm (#5)) and one for single wire (up to 22 mm (#7))

• AFS 3 (Advanced Feeding System) Generation III

• The pressure exerted on each individual wire

• Multi-wire pre-feeder

• Motorised collection trolley, belt conveyor and chain collector conveyor are available

• Bending pins accordingly to international rules

• The payoffs provide automatic motorization and are available in 2 versions: for rolls up to 5 t or up to 8,3 t

Request information

Planet 26 Plus

SHAPE FORMER AND STIRRUP BENDER FROM COIL

COIL ∅10 - ∅26 mm (#3 - #8)

• Single wire

• AFS: pressure control on the two wires individually

• The 2-groove rollers characterized by different profiles and sizes

• Multi-wire pre-feeder

• Multi-wire pre-feeder (single wire/double wire version)

• Motorised collection trolley, belt conveyor and chain collector conveyor are available

• Bending pins accordingly to international rules

• The payoffs provide automatic motorization and are available in 2 versions: for rolls up to 5 t or up to 8,3 t

Request information

Planet 26 Plus Stainless Steel

SHAPE FORMER AND STIRRUP BENDER FROM COIL

COIL ∅10 - ∅26 mm (#3 - #8)

• Single wire

• The processing of stainless steel INOX in coil

• AFS: pressure control on the two wires individually

• The 2-groove rollers characterized by different profiles and sizes

• Multi-wire pre-feeder

• Motorised collection trolley, belt conveyor and chain collector conveyor are available

• Bending pins accordingly to international rules

• The payoffs provide automatic motorization and are available in 2 versions: for rolls up to 5 t or up to 8,3 t

Request information

Planet 22 Plus

SHAPE FORMING AND STIRRUP BENDING FROM COIL

COIL ∅10 - ∅22 mm (#3 - #7)

Double wire up to ∅16 mm (#5)

AFS 3 (Advanced Feeding System) Generation III

The pressure exerted on each individual wire

Complete power unit with winch, portable straightening unit and motorized pre-driving roller for pre-straightening

Motorised collection trolley, belt conveyor and chain collector conveyor are available

Bending pins accordingly to international rules

The payoffs provide automatic motorization and are available in 2 versions: for rolls up to 5 t or up to 8,3 t

Planet 22 Plus W Multiradius

SHAPE FORMING AND STIRRUP BENDING FROM COIL

COIL ∅10 - ∅22 mm (#3 - #7)

• Double wire up to ∅16 mm (#5)

• Rollers are equipped with 3 grooves: two are dedicated to the simultaneous processing of 2 wires (up to 16 mm (#5)) and one for single wire (up to 22 mm (#7))

• AFS 3 (Advanced Feeding System) Generation III

• The pressure exerted on each individual wire

• Multi-wire pre-feeder

• Motorised collection trolley, belt conveyor and chain collector conveyor are available

• Bending pins accordingly to international rules

• The payoffs provide automatic motorization and are available in 2 versions: for rolls up to 5 t or up to 8,3 t

• The automatic "Multiradius" method for curved products with multiple radii of curvature and large rings

Request information

Planet F13

• DIAMETER

Single wire: from ∅5 - ∅13 mm / #2 - #4

Double wire: from ∅5 - ∅10 mm / #2 - #3

• AFS2: AN INNOVATIVE SOLUTION FOR COIL

AFS2 is a straightening system able to control the effect of wire rotation on its own axis, that has origin during the pulling phase. Therefore, closed stirrups and straight bars can always be produced. The exclusive design of the innovative straightening group prominently increase the meeting point between infeed rollers and the two wires, so the correct traction is guaranteed. The coil ribs deformity are reduced at the least without modify the mechanical characteristics of wires, typical in traditional straightening systems.

• CONTROLLED STRAIGHTENING

The combined action between the and the AFS2 on-screen electronic pointer provides a real and full automated automatic control of all straightening functions.

• OTHER FEATURES:

- A double traction for any shape

- No restrictions on shapes and dimensions

- Gravity for quality