Combi Weld / Twin

ELECTRO-WELD MESH MACHINES FROM COIL

High customization: various panel or roll stacking, tying, and storage systems can be customized to meet specific production needs.

Wide range of configurations: P-C Weld/Twin Weld are available in various versions with production capacities ranging from single welding units (P-C-Combi Weld) to double units (P-C-Combi Twin Weld). They also offer customizable solutions for minimum/maximum pitches (longitudinal and transverse), mesh dimensions, and strokes per minute.

Cost reduction: process optimization with fewer machines and operators leads to significant cost savings per ton of mesh produced.

Versatility: the multiple versions available allow for adaptation to any production and layout requirement, ensuring maximum flexibility.

Tailor-made solutions: the use of modular and standardized technologies allows for the creation of a customized system based on the customer's specific requirements.

Components and accessories:

Here is an overview of the main devices and accessories that can be integrated into the systems:

Pay-off unit: unwinds the wire from the coils smoothly and controllably, ensuring constant tension during the welding process.

Straightening machines: eliminate any curvature of the wire, ensuring maximum precision in laying and welding.

Welding cages: consisting of electrodes arranged longitudinally and transversally, they generate the welds that join the wires together.

Cutting unit: cuts the mesh into panels or rolls of the desired length.

Stacking and storage systems: automate the movement and positioning of mesh panels or rolls, optimizing workflows and storage of the finished product.

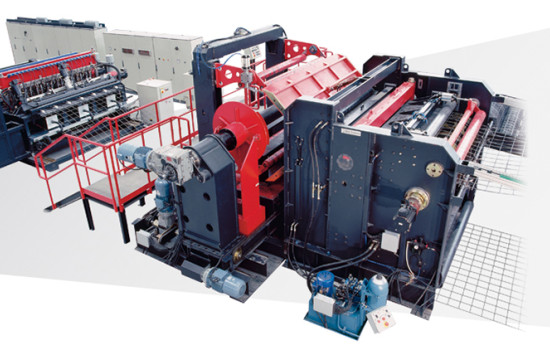

Combi Weld

ELECTRO-WELD MESH MACHINE FROM COIL COMBI WELD (mesh sheets+rolls)

LW ∅3.4 – 8 mm (#2) mesh sheets

LW ∅3.4 – 6 mm (#2) mesh rolls

CW ∅3.4 – 8 mm (#2) mesh sheets

CW ∅3.4 – 6 mm (#2) mesh rolls

Versatile production: produces both panels and coils of electro-welded mesh.

Thin wire capability: handles wire diameters up to 6 mm.

Fully automated: encompasses wire feeding, positioning, welding, cutting, and product handling.

High-speed production: designed for maximum output.

Precise welding: utilizes multiple transformers for uniform current distribution.

Automated product handling: includes automatic cutting, evacuation, and stacking of both panels and coils.

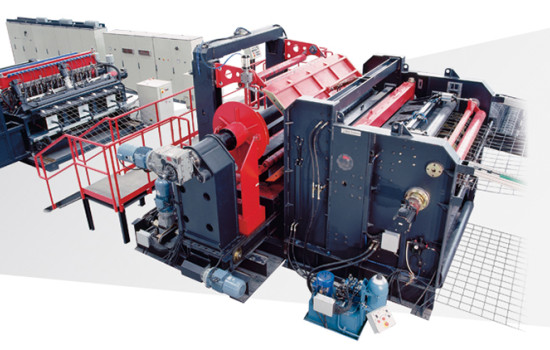

Combi Twin Weld

ELECTRO-WELD MESH MACHINE FROM COIL COMBI TWIN WELD (mesh sheets+rolls)

LW ∅3.4 – 8 mm (#2) mesh sheets

LW ∅3.4 – 6 mm (#2) mesh rolls

CW ∅3.4 – 8 mm (#2) mesh sheets

CW ∅3.4 – 6 mm (#2) mesh rolls

Twin welding unit and combined production: employs two welding units to produce both panels and coils of electro-welded mesh.

Doubled production speed: achieves nearly double production rate due to faster longitudinal wire advancement.

Fully automated: encompasses wire feeding, positioning, welding, cutting, and product handling.

Thin wire capability: handles wire diameters up to 6 mm.

High-speed production: designed for maximum output.

Precise welding: utilizes multiple transformers for uniform current distribution.

Automated product handling: includes automatic cutting, evacuation, and stacking of both panels and coils.