Stepweld

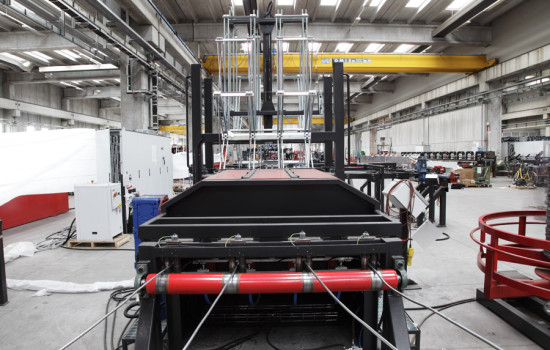

TRENCH MESH WELDING PLANTS FROM COIL OR PRE-CUT LENGTHS

STEPWELD series plants produce high-quality welded mesh, characterized by single or double panels (even overlapping), composed of a minimum number of 2 to 8 longitudinal wires whose diameter range may be between 4 and 20 mm.

The cross wire feeds may have a diameter range from 4 to 12 mm and as in the case of the longitudinal wire feeds they can be in the form of of wire coil or pre-cut bars.

Key features:

High productivity: STEPWELD plants guarantee rapid and efficient production, with minimized set-up times.

Reliability and robustness: Built with high-quality materials, STEPWELD plants are designed to last over time and withstand intensive use.

Versatility: STEPWELD models are available in various configurations to meet specific production needs.

Superior quality: The combined action of a series of exclusive devices guarantees a finished product of the highest quality.

Ease of use: STEPWELD plants are easy to configure and use, thanks to an intuitive control system.

Safety: All STEPWELD plants comply with the latest safety regulations.

Available models:

STEPWELD M: For the use of longitudinal and transverse wires made from pre-cut bars.

STEPWELD H: For the use of bars for the longitudinal wires and wire mesh for the transverse wires.

STEPWELD S: For the production of single or double panels with high levels of productivity.

STEPWELD 4S: For the simultaneous production of two identical and overlapping mesh panels, with even higher levels of productivity.

Additional options:

Automatic tying system: Eliminates the need to tie the mesh bundles manually, maximising plant productivity.

Automatic packaging machine: for stacking multiple bundles of tied mesh, increasing the storage area and optimising lifting and evacuation operations.

Stepweld M

TRENCH MESH WELDING PLANTS FROM COIL OR PRE-CUT LENGTHS

Feeding:

Pre-straightened and pre-cut bars for both longitudinal and cross wire feeding.

Longitudinal bar insertion:

Manual, semi-automatic, or automatic.

Production process:

Fully automatic (cross wire insertion, mesh forming, storage and evacuation).

Welding unit:

Pneumatic cylinders with software-controlled transformers for uniform current distribution across welding points (number proportional to mesh width).

High productivity:

Suitable for high-volume production of electro-welded mesh.

Maximum mesh width: 1600 mm.

Request information

Stepweld S

TRENCH MESH WELDING PLANTS FROM COIL OR PRE-CUT LENGTHS

Feeding:

Coil of wire (round cold drawn or hot rolled,smooth or ribbed) for longitudinal and transverse lines.

Product:

Lattice plane girders (not electro-welded mesh) with a maximum of two longitudinal wires.

Production process:

Fully automatic (straightening, positioning, welding, cutting).

Longitudinal wire straightening:

Use of rotors with hard metal parts.

Welding unit:

Pneumatic cylinders and software-controlled transformers.

Panel evacuation and stacking:

Automatic.

High productivity:

Ideal for the production of lattice plane girders, particularly suitable for residential trenches.

Stepweld H

TRENCH MESH WELDING PLANT FROM COIL OR PRE-CUT LENGTHS

Feeding:

Pre-straightened and pre-cut bars for longitudinal lines.

Coil of wire (round cold drawn or hot rolled,smooth or ribbed) for cross lines (hybrid feeding).

Longitudinal bar insertion:

Manual, semi-automatic, or automatic.

Production process:

Fully automatic (cross wire insertion, mesh forming, storage and evacuation).

Welding unit:

Pneumatic cylinders.

Number of transformers proportional to maximum mesh width for uniform welding.

Software control of welding parameters.

High productivity:

Suitable for high-volume production of electro-welded mesh.

Maximum mesh width: 1600 mm.

Request information

Stepweld 4S

TRENCH MESH WELDING PLANT FROM COIL OR PRE-CUT LENGTHS

High productivity: simultaneous production of 2 overlapping panels.

Double line: 2 separate lines for the formation of cross wires.

Final product: electro-welded mesh with a maximum of 4 and a minimum of 2 longitudinal wires.

Automatic process: fully automatic production after setting parameters.

Efficient welding: welding unit with 2 insertions and a series of opposing welding electrodes.

Reduced footprint: panels with opposite cross wires for more compact stacks.

Unloading: automatic unloading of panels.